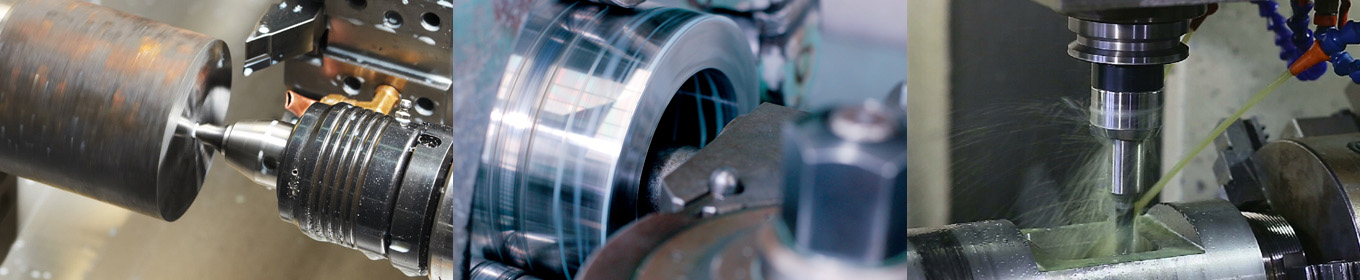

The selection of the proper screw for a given processing application is critical to its success. We offer full service for your specific plasticizing components' needs for injection molding machines, single screw extruders and blow molding machines, including OEM and custom design based on applications.

Screw custom design and manufacture should be based on the resin or resins to be processed. If a number of different resins are being processed with the same screw, that screw should be designed to optimize its performance, allowing for all the materials to be processed with reasonable success. Our design team will work closely with you to custom design the screw to suit your application. This ensures increased machine productivity, better melt quality while maintaining output quality and longer screw and barrel life.

Your prints, drawings, dimensions or any other OEM files are also welcomed for us to work from, we can recreate or rebuild any associated part you need.